VideoRay drives safe, effective underwater exploration leveraging AI and today’s newest technologies

Vicor Powering Innovation podcast discusses the proliferation of ROV applications and how VideoRay is responding to new underwater missions

Robotics solutions and case studies

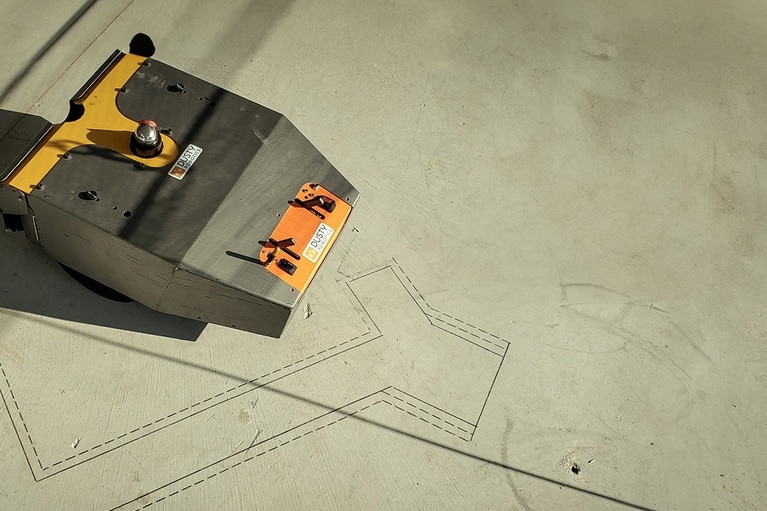

Case study: Sewer inspection robot

Improved sensors, autonomy, mobility and AI (allowing deep learning) is enabling inspection robots to replace humans, especially in hazardous or confined areas like inside pipelines or in storage tanks. Manufacturers are looking for smaller, more robust solutions with ever improved resolution, repeatability and operating range. This manufacturer of tethered sewer inspection robots was looking to improve the sensor resolution and quality of video images without increasing the size of the platform. The key goals were:

The 48V (SELV) supply to the tether was provided by a PFM AC-DC converter. On board the robot the three rails were provided by three individual regulators. Key benefits were:

The power delivery network: The 48V tether supply was provided by a PFM AC-DC converter. At the robot the low power 5V and 3.3V rails were provided by ZVS Buck regulators. The higher power 12V motor supply rail was provided by an array of three ZVS Buck-Boost converters that compensated for large voltage drops in the 600m tether. To analyze this power chain go to the Vicor Whiteboard online tool.

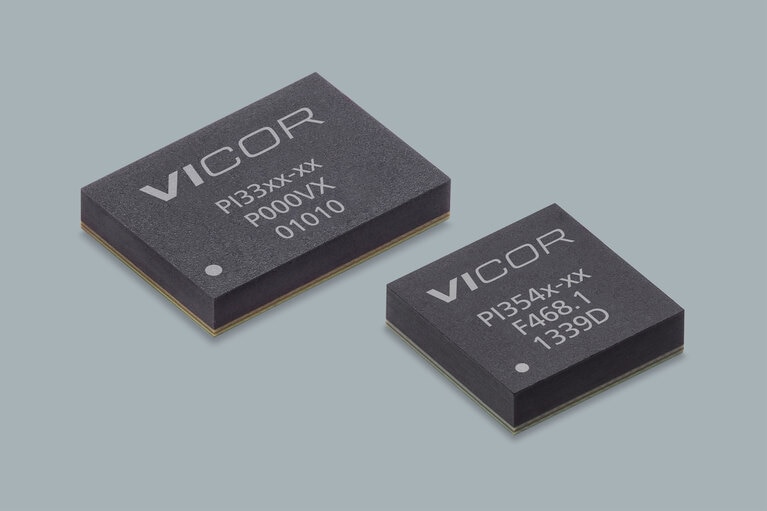

Inputs: 12V (8 – 18V), 24V (8 – 42V), 48V (30 – 60V)

Output: 2.2 – 16V

Current: Up to 22A

Peak efficiency: Up to 98%

As small as 10.0 x 10.0 x 2.56mm

Input: 8 – 60V

Output: 10 – 54V

Power: Up to 150W continuous

Efficiency: Over 98%

10.5 x 14.5 x 3.05mm

VideoRay drives safe, effective underwater exploration leveraging AI and today’s newest technologies

Vicor Powering Innovation podcast discusses the proliferation of ROV applications and how VideoRay is responding to new underwater missions

The future of long-haul trucking is accelerating autonomously on a freeway near you

Kodiak autonomous technology revolutionizes long-haul trucking. Learn more about Vicor power modules that drive mission critical ‘seeing’ sensors

Next generation hydrogen powered drones are doing search and rescue, saving lives

Doosan Mobility’s life-saving drones using hydrogen fuel cells and high-density power modules, enabling 5x longer flight time than lithium ion batteries

From toys to construction site tools, OLogic brings robotic ideas to life

OLogic extols high-density power modules to drive today’s robotic revolution