VideoRay drives safe, effective underwater exploration leveraging AI and today’s newest technologies

Vicor Powering Innovation podcast discusses the proliferation of ROV applications and how VideoRay is responding to new underwater missions

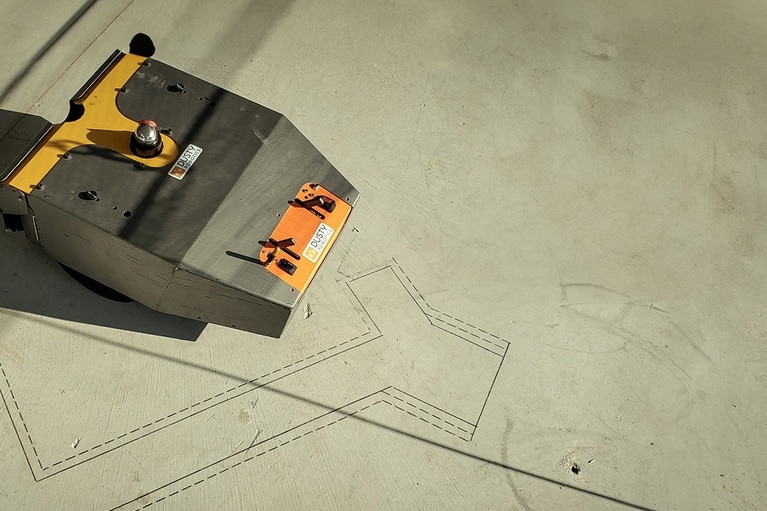

Some mobile robots need to be connected to a base station via a tether cable. In applications such as underwater inspection, the tether allows for extended operation and high-bandwidth data transfer from cameras in otherwise noisy and harsh environments. The thinner and lighter the cable, the further and longer these robots can operate, but thinner cable limits power delivery from traditional PDNs. The Vicor modular approach enables higher voltages to be transmitted over the cable, reducing the cable size and weight without compromising power. The small size and low weight of Vicor modules also makes the robots lighter and able to increase payloads.

Build better robots using modular powerWATCH now

A compact, lightweight, and efficient PDN is necessary to make a 400V tether usable for thrusters to propel and underwater robot as well as to power control systems, cameras, and sensors that operate from 12V to 48V. This example shows a DCM isolated, regulated DC-DC converter not only creating a 48V bus, but also directly driving the robots thrusters. The 48V is then converted down to 12V and 24V using BCM488 non-isolated, fixed-ratio DC-DC converters for onboard systems. BCMs can achieve up to 98% efficiency and power densities up to 2.4kW/in3, allowing the robots to work longer and take on more payload.

Input: 9 – 420V

Output: 3.3, 5, 12, 13.8, 15, 24, 28, 36, 48V

Power: Up to 1300W

Efficiency: Up to 96%

As small as 24.8 x 22.8 x 7.21mm

Input: 800 – 48V

Output: 2.4 – 55.0V

Current: Up to 150A

Efficiency: Up to 98%

As small as 22.0 x 16.5 x 6.7mm

VideoRay drives safe, effective underwater exploration leveraging AI and today’s newest technologies

Vicor Powering Innovation podcast discusses the proliferation of ROV applications and how VideoRay is responding to new underwater missions

The future of long-haul trucking is accelerating autonomously on a freeway near you

Kodiak autonomous technology revolutionizes long-haul trucking. Learn more about Vicor power modules that drive mission critical ‘seeing’ sensors

Next generation hydrogen powered drones are doing search and rescue, saving lives

Doosan Mobility’s life-saving drones using hydrogen fuel cells and high-density power modules, enabling 5x longer flight time than lithium ion batteries

From toys to construction site tools, OLogic brings robotic ideas to life

OLogic extols high-density power modules to drive today’s robotic revolution