High-bandwidth power modules quell the disruption of high-voltage line ripple rejection

Vicor DC-DC converters combine high bandwidths with soft switching topologies to reduce EV ripple rejection more effectively than conventional solutions

Power system thermal issues are perhaps more important than ever: the need for greater energy efficiency, higher output power and increased density must be met despite reducing design cycle times to meet challenging time-to-market requirements. Although the challenge of thermal design is not new, it continues to present an increasing challenge to power engineers.

The Vicor ChiP packaging technology introduced a revolution in power system thermal design with the capability to cool the device on both sides. Although this greatly improves the efficiency with which heat can be removed, enabling unprecedented power density, this approach can add to the complexity of thermal design and calculations.

Fortunately, there are several tools and white papers that are available to power system designers to radically simplify thermal design of even the highest-performance components.

If a component is not sufficiently cooled, the junction temperature of the semiconductors inside can increase to a level that can cause incorrect operation or permanent failure. There are three basic methods to remove heat from a power component, which all take advantage of the fact that heat flows from a higher to a lower temperature region:

Although all three should be considered when designing a thermal solution, the primary way power engineers design in cooling is the addition of a heatsink to provide conductive cooling and the movement of air for convection.

Convective cooling can be increased by increasing the movement of air by forcing it through the system using a fan. Fans, however, add to the system cost and size, increase noise and can be the least reliable part of a system, so avoiding forced air cooling where possible is always preferable.

The first stage in a thermal design is often the Vicor thermal calculator. This tool allows you to calculate maximum output power, maximum thermal impedance, the maximum ambient temperature or the temperature rise. Although this tool is relatively straightforward, it allows power designers to understand the challenge they must overcome and determine how complex it will be to deliver the required cooling.

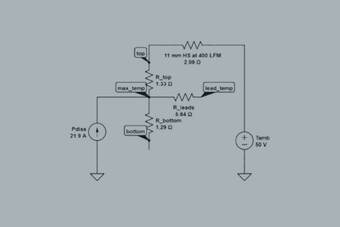

Thermal circuit models are a very effective way to calculate the performance of any cooling system. Vicor offers a White Paper explaining how to use circuit models in thermal calculations, which provides a comprehensive introduction to this technique. These models use electrical components as analogs to thermal characteristics: resistors represent thermal resistance, current sources are used instead of heat sources and temperature sources are simulated with voltage sources. This approach makes analysis simpler, allowing engineers to use familiar electrical components.

Different packages will require different thermal circuit models to reflect their construction. In particular, the model of a ChiP package that offers double-sided cooling will be different from a conventional component that is only cooled on one side. A white paper is available that explains the thermal circuit models of different Vicor components.

Although circuit models are an effective way of analyzing a thermal design, making the calculations by hand can be very time consuming. Fortunately, Vicor simulator tools include the capability to simulate thermal behavior, allowing engineers to accurately determine the operating conditions with just a few clicks.

The simulation tools are easy to use, and a recent webinar presented by Mike DeGaetano, a Vicor Systems Applications Engineer, walks through how to use simulation to create cooler systems.

Our online tools include some powerful features to enable simulation of different conditions, heatsinks and even the use of cold wall cooling. Check out the recent blog post that explains how to get the most from Vicor thermal simulations.

Sometimes it is just too difficult to deliver the required amount of cooling in a high-performance system unless radical steps are taken. At the Open Compute Project Summit 2018, Vicor and 3M demonstrated a way to overcome the relatively low thermal conductivity of air: liquid immersion cooling. Although this approach tends to be limited to applications such as supercomputing, the video of the coolant flowing over power components is still very impressive!

As the leader in delivering high-performance, high-density power components, Vicor pioneers new power packages. Extensive engineering work and a very rigorous approach to thermal testing has allowed us to create innovations such as ChiP and VIA packaging technologies.

Tool: product simulators

Tool: thermal calculators

White Paper: Use of Circuit Models in Thermal Calculations

High-bandwidth power modules quell the disruption of high-voltage line ripple rejection

Vicor DC-DC converters combine high bandwidths with soft switching topologies to reduce EV ripple rejection more effectively than conventional solutions

The future of standardized defense platforms using MOSA, SOSA and VPX open architectures

Using open standards to increase interoperability, scalability, reliability, reduce system costs, and minimize the number of custom electronics designs

Delivering higher power density and low noise for New Space applications

Patented power design techniques and architectures needed to deliver optimal power and low noise for space communications applications

Optimizing high-density power design: modular vs. discrete

There are several important design variables to consider when evaluating the power module design process