Compact power modules allow space for advanced sensors that improve security and performance

Inspection robots can monitor infrastructure more frequently and allow for rapid remediation before problems occur, saving lives, time, and money

Case study: Logistic robots

Logistic robots like AMRs and AGVs provide inventory management and order fulfillment tasks within large warehouse environments and can have different sizes and functionalities. These robots are fueled by 24V to 72V batteries with charging performed on an as-needed basis, making power conversion efficiency – along with size and weight – critical. Power conversion is more challenging with navigation, sensing and safety requirements increasing. The key goals were:

A logistics robots’ job is to be productive and move safely through warehouses full of obstacles. Vicor high-performance power modules help save weight and space on board, allowing for more accessories to ensure safe operation. The power delivery network can be easily reconfigured and used for other platforms with different power requirements by simply changing or adding modules.

Zero-Voltage Switching topology provides 97.4% efficiency

Power modules can be scaled to meet diverse power requirements

Compact, high-density power modules optimize available space

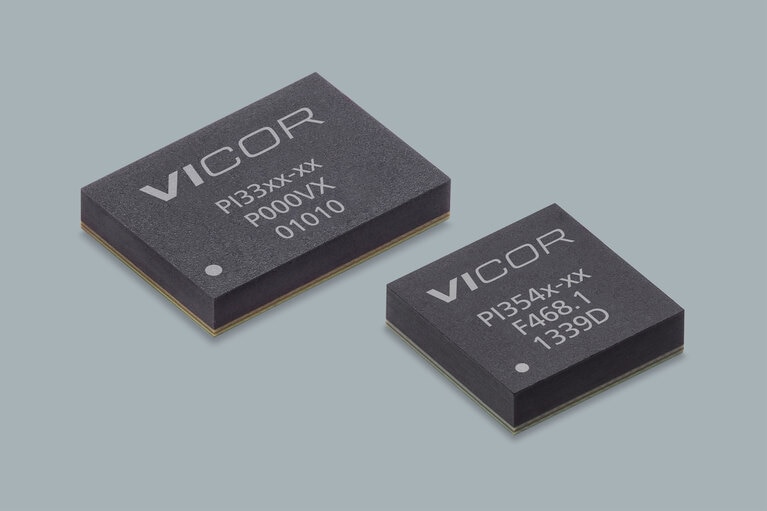

The PRM™ power module, a high-performance buck-boost regulator creates an intermediate bus of 24V to 48V with 96 to 98% efficiency to power servos and additional downstream power modules, including fixed ratio NBMs, ZVS buck and ZVS buck-boost regulators. All modules can also be paralleled for higher power conversion.

非絶縁 電圧変換比固定

入力電圧: 36 – 60V

出力電圧: 7.2 – 15.3V

出力電流: 最大2400W

効率: 98%以上

23 x 17 x 5.2mm 他

非絶縁 レギュレータ

入力電圧: 12V (8 – 18V), 24V (8 – 42V), 48V (30 – 60V)

出力電圧: 2.2-16V

出力電流: 最大22A

ピーク効率: 最大 98%

10.0 x 10.0 x 2.56mm 他

The second powertrain architecture highlights the use of direct conversion from the battery to the point-of-load. PRM™, ZVS Buck, and ZVS Buck-Boost regulators support these applications. One example is the PI3740 ZVS Buck-Boost regulator which provides more than 100W of power from a 10 x 14 x 2.5mm SiP package with peak efficiencies of up to 96%.

Compact power modules allow space for advanced sensors that improve security and performance

Inspection robots can monitor infrastructure more frequently and allow for rapid remediation before problems occur, saving lives, time, and money

High-efficiency power modules maximize system run-time and improve productivity

Logistic robots like AMRs and AGVs provide inventory management and order fulfillment tasks within large warehouse environments

Lightweight and efficient power modules extend delivery routes and save space to carry more goods

Last-mile consumer delivery of groceries, take-out food and online consumer items is the mission-critical task of autonomous robots

頑丈で高信頼性、高効率の電源モジュールを使い、過酷な環境でも稼働時間を延ばす (英)

Harvesting robots perform various tasks on farms, often autonomously and are equipped with sensors, cameras, and GPS systems to navigate their environment